Value of Design Award

The Village Goldsmith 6 The Floeting Diamond

-

Pou Auaha / Creative Directors

Ian Douglas, Christine Douglas, Chris Benham

-

Ringatoi Matua / Design Director

Ian Douglas

-

Ngā Kaimahi / Team Members

Alex Whitney, Chris Warren, Callum Allen, Allette Ockhuysen, Dan Palmer -

Kaitautoko / Contributor

Grant Lumsden

Description:

"Perfection is achieved, not when there is nothing more to add, but when there is nothing left to take away." Antoine de Saint-Exupéry.

Forbes described it as a ‘revolutionary setting’ and Idex has said that this setting “does what no setting has ever managed before.” Awarded a prestigious international 2022 Red Dot Award for Outstanding Product Design the Red Dot team described the Floeting technology as ‘remarkable.’

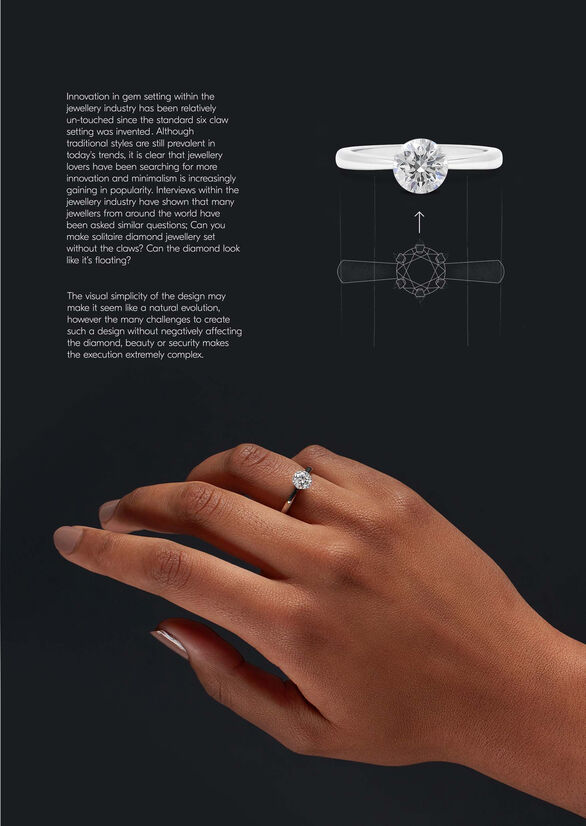

Around the world, clients have been asking "Can you make this design without claws or clasps?”. Of course, under traditional jewellery manufacturing processes, this was never possible... Until now. Current setting techniques for solitaire diamonds, require a craftsman to attach metal to the upper surface of the diamond to hold it in the setting. This results in a distraction from the purity of the diamond and a reduction in the sparkle. To hold a solitaire diamond safely and with no reduction in the “sparkle” or light return is the epitome of excellence in this field and this is now possible with our patented Floeting Diamond cut and setting process. The process required for setting does not require a traditional trained jeweller to complete which saves costs in the manufacturing process.

The custom designed patented diamond cut allows a micro-engineered setting to be secured below the widest part of the diamond, creating a top-down view that is free of prongs or overarching metal. The elegant and minimalist design directs all attention to the diamond’s sparkle and scintillation that is maximised by this setting.

This innovation has taken 10 years of research and development across different industries and countries as we have tested and retested processes to achieve this final product.

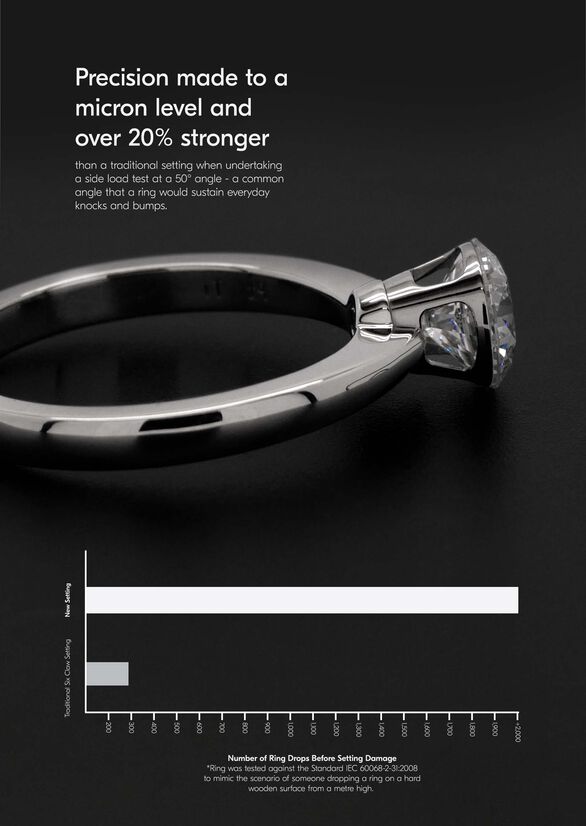

Most current gemstone settings are made from traditional precious metals, which wear down over time or are damaged through everyday wear and tear putting the diamond at risk of coming lose and needing to be replaced, often resulting in a cost to the owner and/or their insurer. To prove The Floeting Diamonds superior strength, we have conducted extensive independent testing. In a side load test undertaken at a 50° angle, The Floeting Diamond was proven to be over 20% stronger than a traditional setting which showed very early signs of deformation damage. In a side load stress test undertaken at a 90° angle, the traditional setting showed signs of extreme deformation at 77N. In comparison, The Floeting Diamond was completely unaffected at 77N and showed no signs of deformation.

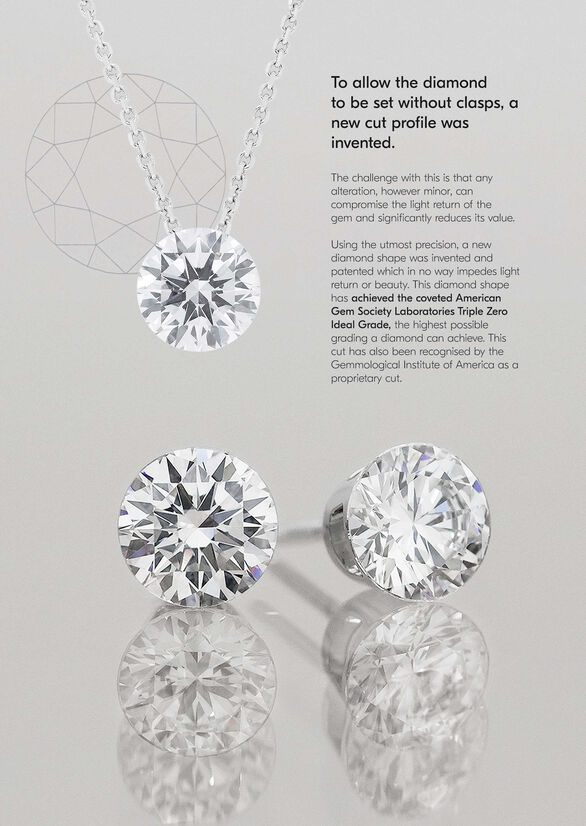

The patented Floeting Diamond Cut has also achieved the coveted “Ideal Grade” from the world's most stringent diamond grading facilities, American Gem Society Laboratories, which is the highest possible grading a diamond can achieve. It has also been recognised by the Gemmological Institute of America, another of the world's leading diamond grading facilities, as a proprietary cut on their diamond grading certificates.