Spatial

Andrew Barrie Lab 14 Billy Pengelly Batchelar McDougall Consulting Y Shelter

-

Pou Auaha / Creative Director

Billy Pengelly

-

Ringatoi Matua / Design Director

Andrew Barrie

-

Ngā Kaimahi / Team Members

Cass Goodwin, Matt Liggins -

Client

Summerhill Charitable Trust

Description:

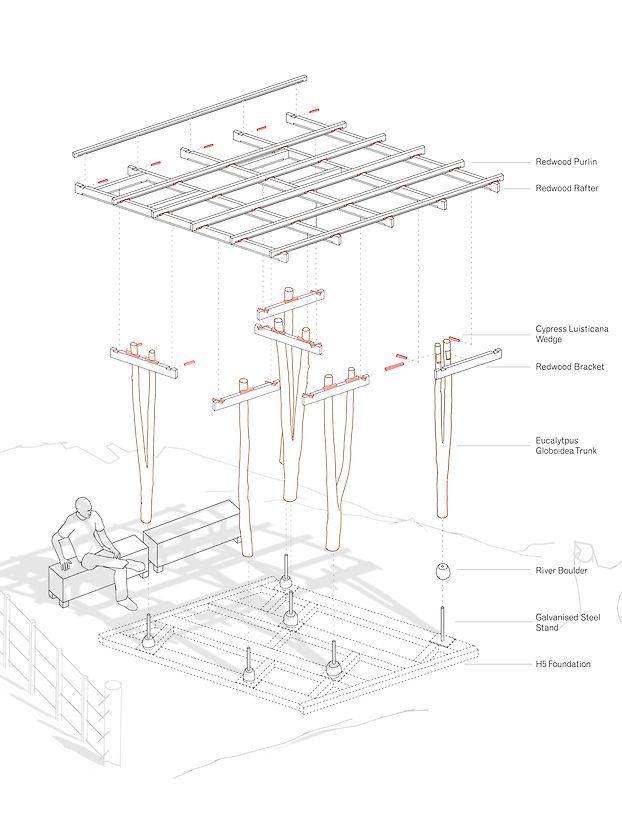

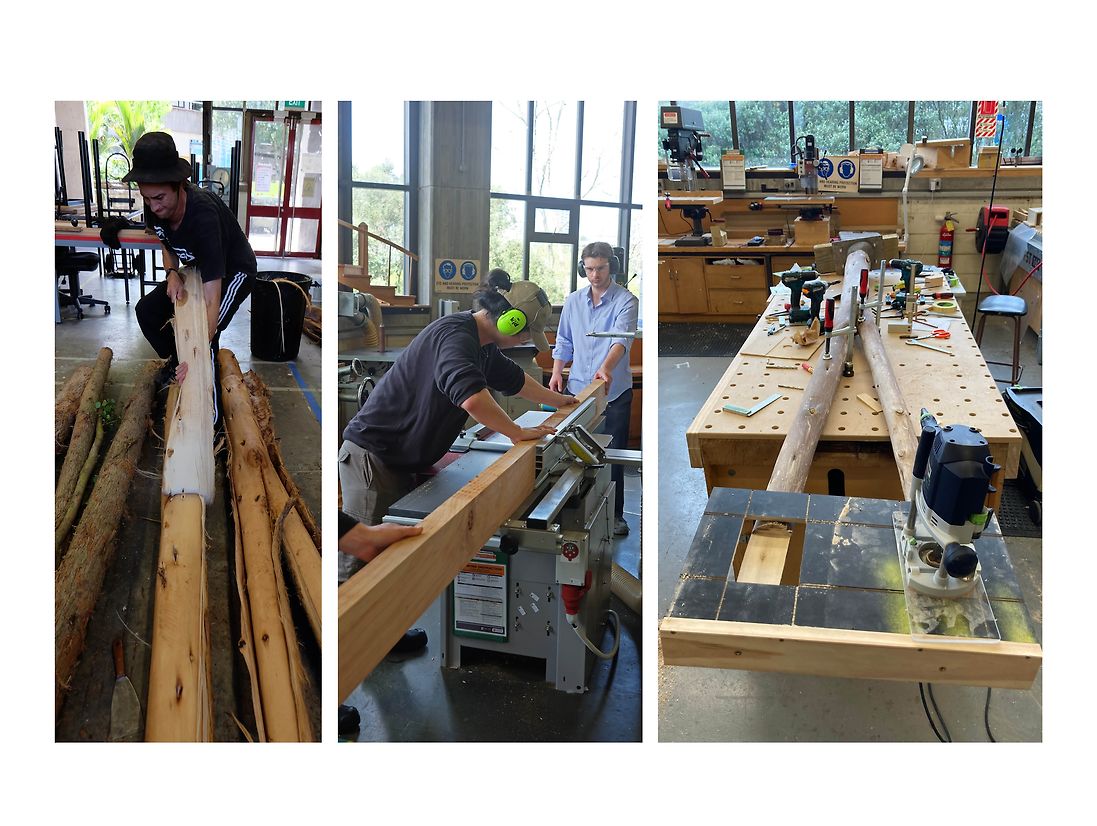

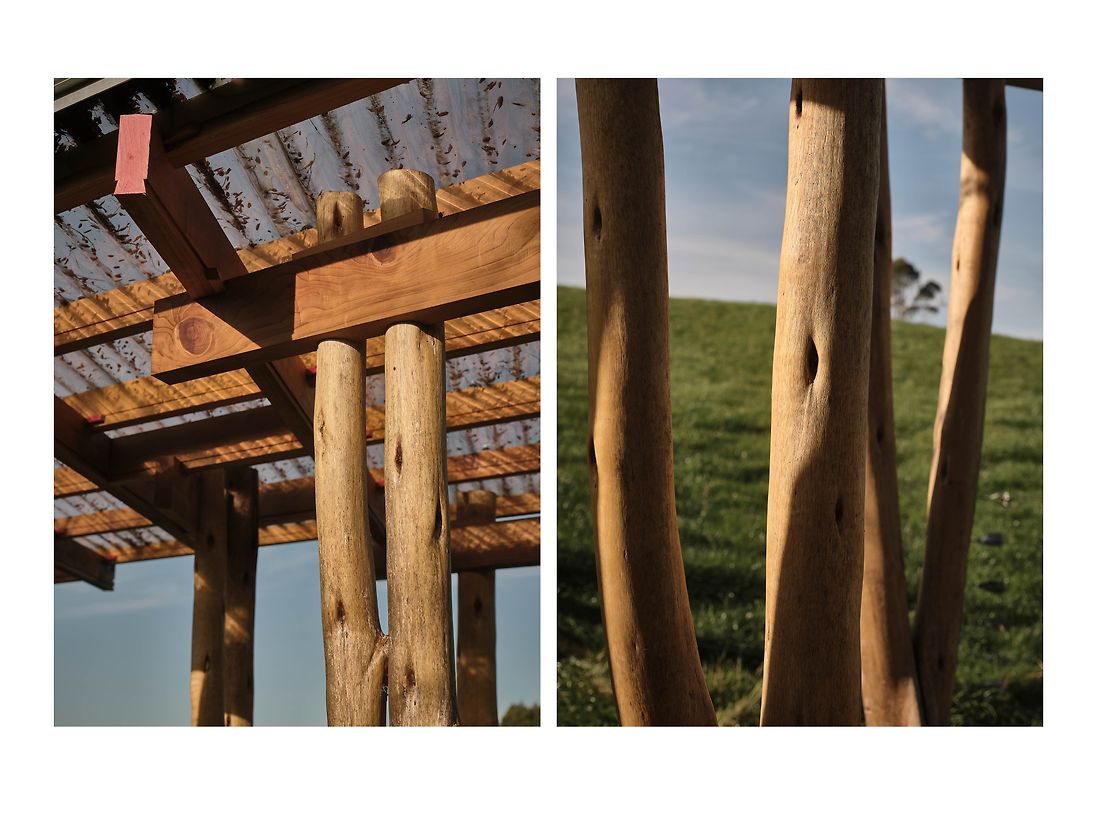

Seeking an alternative to the use of expensive hardwoods or engineered timber in architectural structures, the project makes use of extremely low quality timber: thinnings from a seven year-old commercial stand of Eucalyptus Globoidea. These thinnings, left unprocessed and in the round, were gathered from the forest floor, all cut because they were undesirable non-conforming trees with double leaders and curved trunks. The use of such timber has been explored internationally, often using advanced CNC machines and robotic arms. This technology is both expensive and uncommon in New Zealand, so we sought to develop techniques that required only readily available handheld tools.

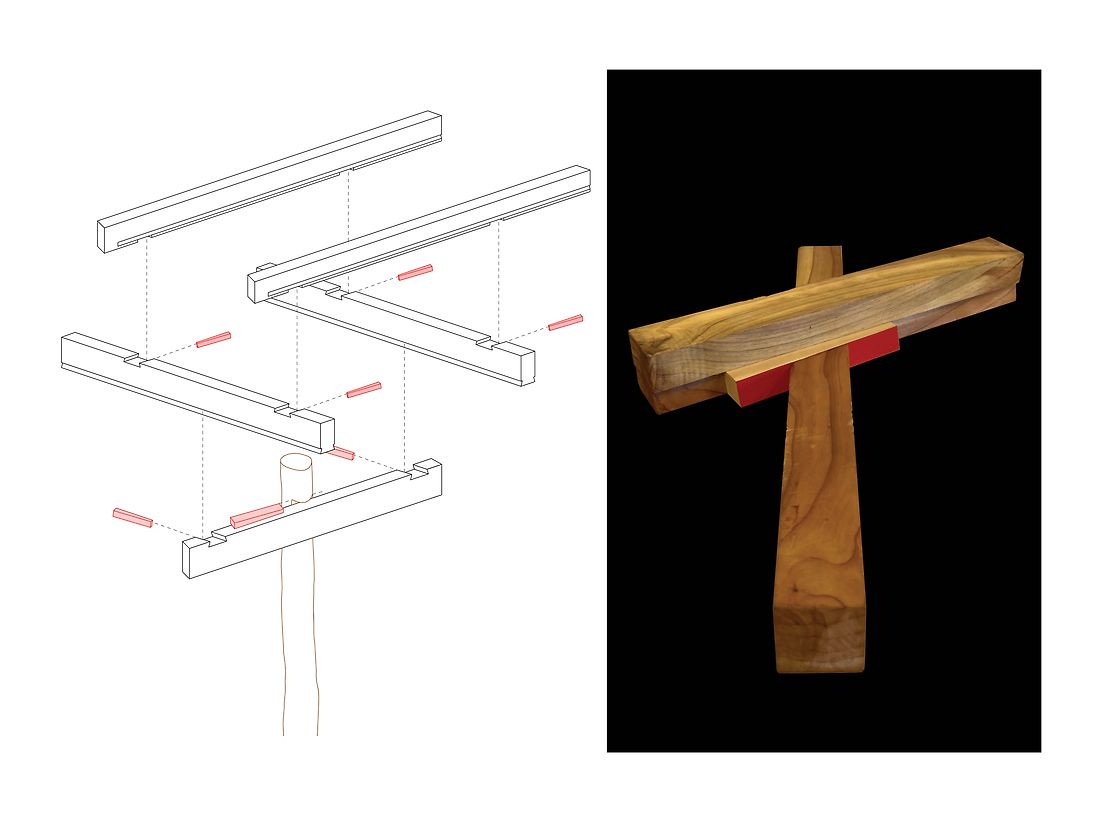

Using timber of such extremely low quality, particularly when left in the round, presents two problems. The first is the instability of the timber, which will warp, twist, and shrink. Further, a lack of straight edges makes accurate measuring or machining difficult. In response, we developed a system of wedged joints that can seamlessly absorb inaccuracies and deformation. The wedges ensure that each joint can be tightly fitted to produce a rigid joint, and can be adjusted and re-tightened as the timber shifts and settles over time. To achieve this, we developed joint cutting techniques that employ simple jigs designed to allow their use on irregular substrates.

The Y-Shelter forms part of a series of experimental timber projects built at Summerhill Recreational Park by staff and students at a New Zealand university. Functionally, the building is a resting place that marks the entrance to the network of forest walking trails. Its budget was tiny: $10,000 for design, materials, fabrication, shipping, and installation. The trunks were supplemented with redwood provided by Summerhill Timbers Ltd; all the timber was grown in the forest where the building was constructed. The project was easily assembled on site, requiring little more than a mallet and without the need for a skilled builder or heavy equipment. Built without the use of nails or screws (excluding the roof fixings), each post, beam, and rafter connection was made using timber-to-timber wedged joints, allowing the structure to be fully prefabricated. Located a 20-minute walk from the nearest road, the design also eliminated the need for concrete in the foundations.

Our goal for this ongoing research is lightweight, sustainable structures that expand the possibilities for timber construction, a key part of our nation’s response to the current climate emergency. The intention for this project was to develop a means of achieving a viable timber structure using extremely low-grade timber—so low it is normally left on the forest floor to rot. The potential impact of this work will be clear: converting what is currently a waste product into a viable construction material. This has become a particularly pressing issue as the forestry industry has come under scrutiny due to the destructive potential of forestry by-products such as slash. In an era where timber is re-emerging as the prevalent construction material, this project serves as a proving ground for the use of natural form timber as primary structural components.