Courtney McLeod, Oliver Mortimer, Keely Harman, Ameka Weston, Nick Holland, Oliver Williams, Hanne Lill Thuresson, Josh Collins, Winston Brinsley, Kareena Annan, Annie Gibson, Dan Clutterbuck, Ali Antaqi, Hamish Maunsell, Koko Andrews, Liam Cosford, Courtney Drake

B1

Credits

-

Tauira / Students

Courtney McLeod, Oliver Mortimer, Keely Harman, Ameka Weston, Nick Holland, Oliver Williams, Hanne Lill Thuresson, Josh Collins, Winston Brinsley, Kareena Annan, Annie Gibson, Dan Clutterbuck, Ali Antaqi, Hamish Maunsell, Koko Andrews, Liam Cosford, Courtney Drake -

Kaitautoko / Contributor

Daniel Harmsworth -

Kaiako / Lecturer

Rodney Adank

Description:

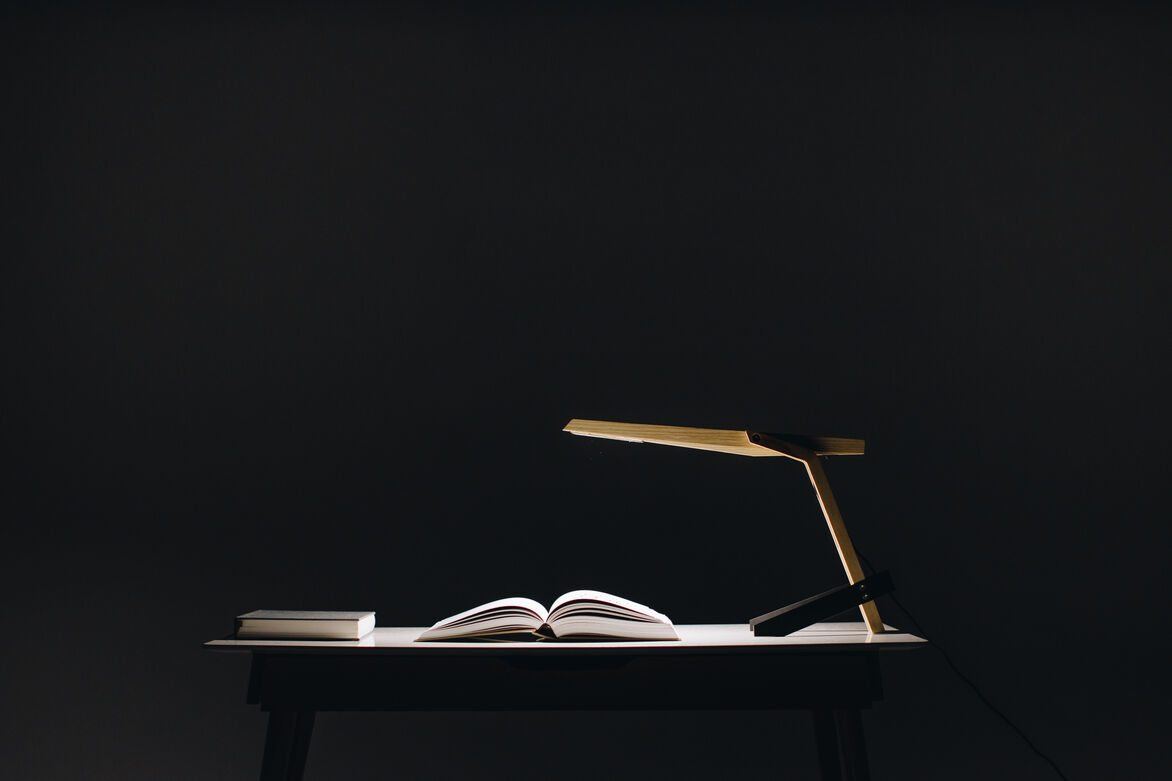

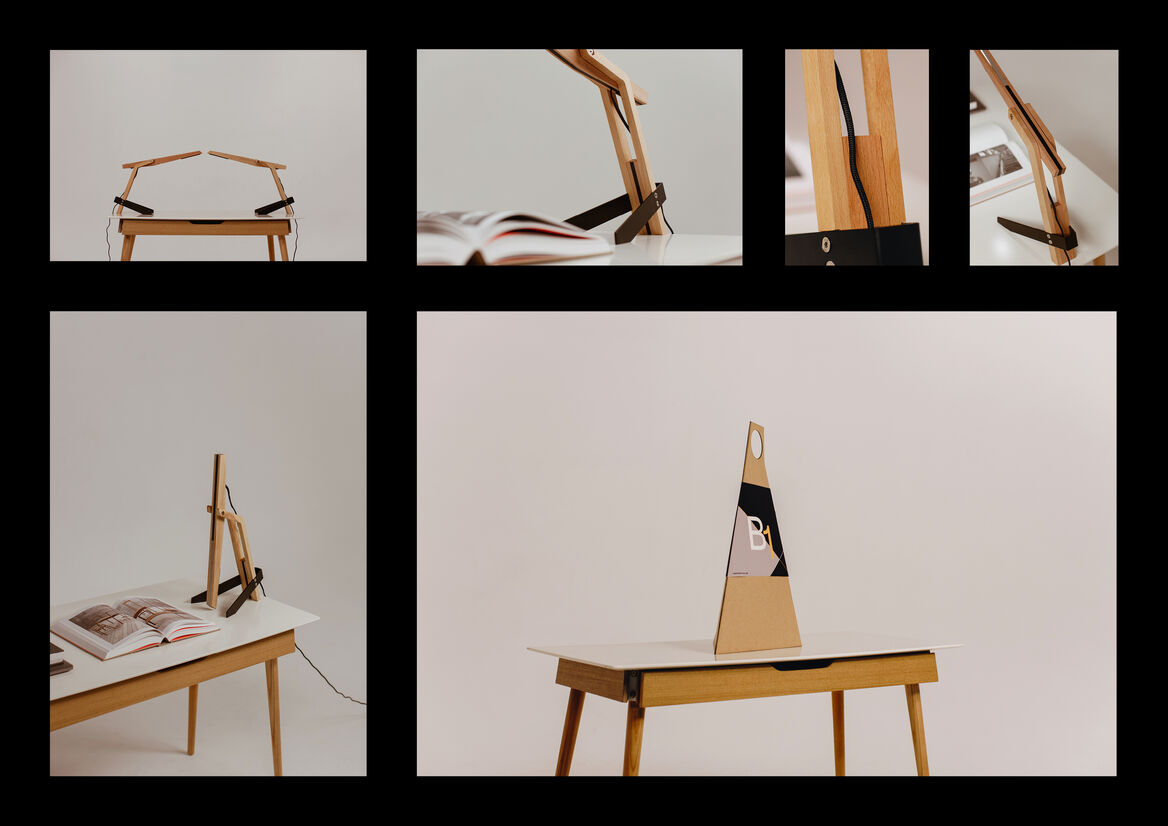

B1 is a contemporary task lamp that references Battle Droids from Star Wars in its form

language and name. The design development of B1 came through an iterative process of visualisation, screening assessments and prototyping to interrogate functional and form aspects critical to the final development of an integrated product design.

The B1 embraces a contemporary aesthetic, imbued with natural timber features, married with energy efficient LED technology and a discrete activation switch. B1 is thoughtfully crafted with a streamline body, sharp lines and considered curves and edges which produce a strong presence in context with a science fiction reference.

The articulation of the designs upper arm, allows for traditional task lamps use, as well as reflective ambient lighting from wall or ceiling to affect mood. This expands the products utility and value in a manner more responsive to domestic environments.

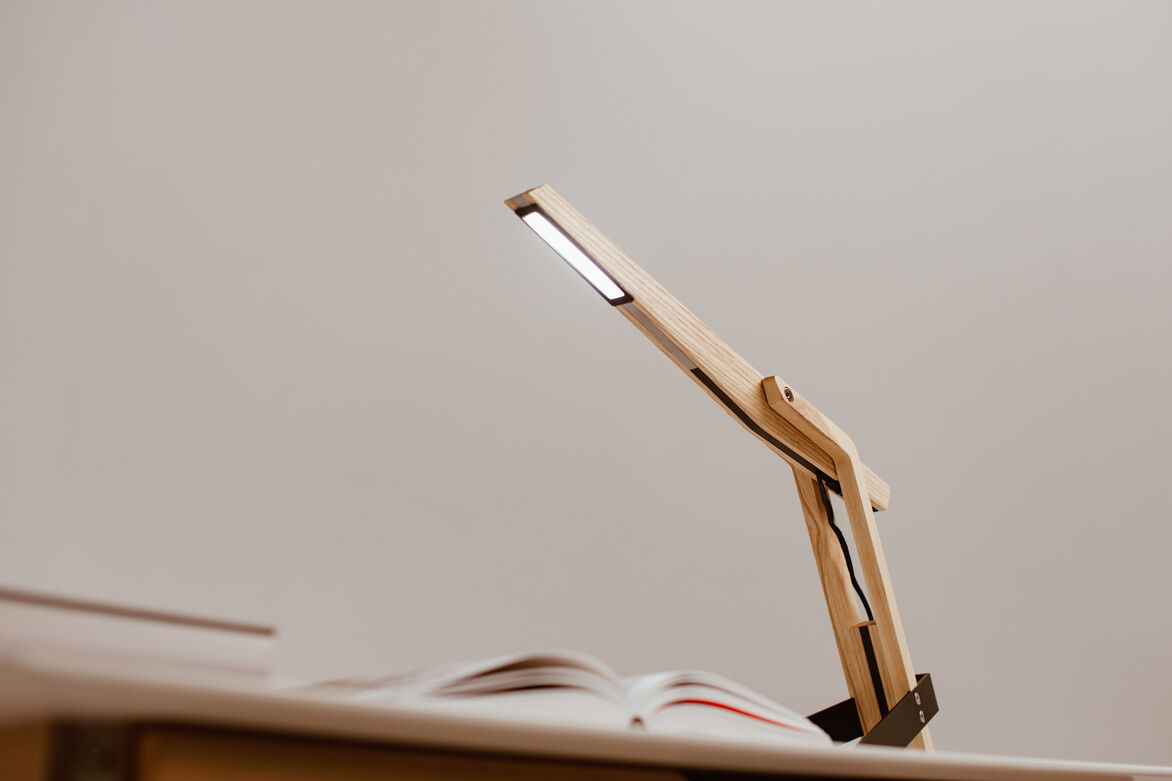

The design strategy embraced with B1, was a mix of integrated and modular architecture. Electrical parts were produced as integrated electrical components that could be fitted within modular components, such as the upper arm, this greatly advanced manufacturability. The modular components allow for aesthetic tuning and customer selection of timbers for particular contexts of use and contributing to a more affective experience.

Technological manufacturability of components was tested with consequent understandings of how particular materials would respond and behave. An example of this was customisable components, such as timber selections that required different accommodations when preparing for CNC machining. Differing strength and machinability characteristics of different timbers altered manufacturing processes.

Developing products with electrical supply comes with legal obligations to comply with

Worksafe standards, and this was an important milestone in the development of B1, which has undergone testing and complies with ANZS 3730, standards for mains power supply to low voltage systems. B1 was manufactured using processes such as SLA and FDM printing, CNC Routering, Laser Cutting, Water Jet Cutting, Milling, and Sandblasting. The lamp’s material make up includes Ash or Beech wood, acrylic, aluminium, photopolymer resin, diffused acrylic, spray paint, and a lead weight.

The three point placement of the base is a feature that means B1 always sits with a

comfortable stance, and one that does not reach into work surface area. To turn on the

lamp, the user simply has to flick the switch under the back end of the arm. In order to adjust the angle of illumination, the user can move B1's arm up or down and the lamp will hold itself at the desired interval due to an internal ‘herth’ gear. This internal development of these components affecting the feel and performance of the product, stretched the team but provided an innovative step in lamp control.

Developed for batch production, B1’s overall form, function and finish were completed to a high standard of functional and aesthetic performance.