Product

Pacific Helmets NZ LTD Haloflex™

-

Pou Auaha / Creative Director

Lee-Anne Glanville-Rothman -

Pou Rautaki / Strategic Lead

Holly Curtis

-

Ringatoi Matua / Design Directors

Sam Milsom, Justin Hughes

-

Ngā Kaimahi / Team Members

Sam Milsom, Justin Hughes, Barnaby Smith, Tristan Kennedy -

Kaitautoko / Contributors

Damian Ryan, Glen Spink, Jeremy Leatham

Description:

Firefighting has always been a profession that has a high degree of danger – the men and women that put themselves in harm’s way to protect us and our property are seen as heroes by many.

PPE over the years has improved at a remarkable rate – improving protection against heat, flame, impacts, even explosion debris, giving our Firefighters the best possible chance to walk from danger and return home to their families at the end of the day.

Unfortunately, we now know that Firefighters and those close to them are put at risk every day from other, unseen dangers and that Cancer is the greatest cause of ill health and death in current and former Firefighters.

The toxins released into the air during a structure fire include heavy metals, asbestos and poly-fluoroalkyl substances or PFAS. The tragedy is that these dangerous chemicals are not left at the fire site but can travel back to the station and even to the firefighters' home and family.

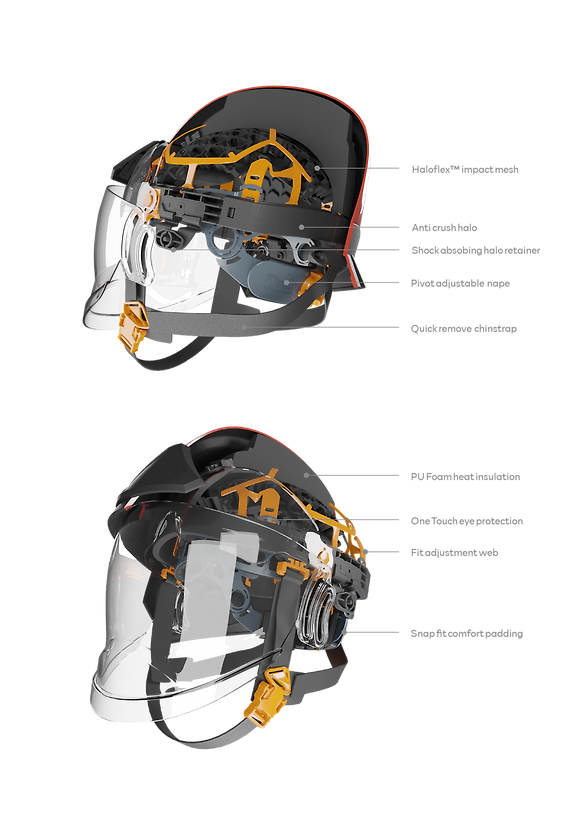

The internationally patented Haloflex™ Impact protection system has been developed for one purpose; to provide the highest level of safety – without compromise.

Our design team went back to the start with Haloflex™, and developed a world first impact protection system that meets and exceeds the brief:

1) Quick and thorough decontamination with minimal absorbent textile components.

2) Superior global impact and fall protection and reduction in TBI (Traumatic Brain Injury) risk.

3) Tool free care and maintenance.

4) 20% weight reduction compared to previous models.

5) Versatility across helmet models and international safety standards.

In a worldwide first, the design team have replaced all particulate and carcinogen absorbing textile parts with innovative componentry that can be washed and dried quickly in a fire stations helmet washing machine. The textile components that do remain are quickly removeable for quick separate laundering or swap out for spares. Historically this has been a skilled, dirty process that takes days for completely dry helmets. A Haloflex™ helmet can be stripped, cleaned and back in service in 45 minutes. All servicing, maintenance and replacement of spare parts are tool free.

The unique clip in padding is specially sourced non-absorbent, antimicrobial pressed and laminated foam.

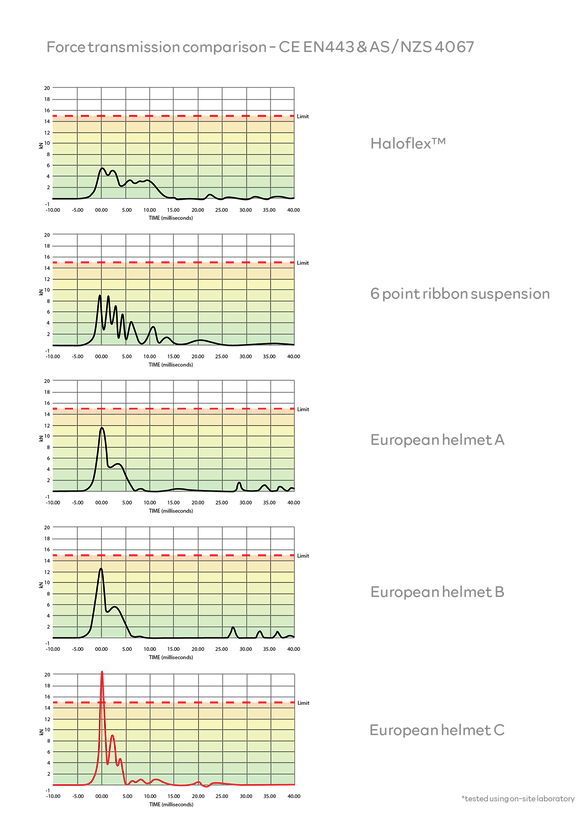

The next level impact protection that Haloflex™ helmets provide is multi-stage, with the Impact mesh being responsible for the lions share. Through iterative design, prototyping and FEA CAD modelling, we arrived at a dynamic design matched with the perfect polymer to slow down and mitigate impact and fall energy to minimize head and traumatic brain injuries better than any helmet before. Certification testing at overseas third-party laboratories proves this.

The Haloflex™ System is currently sold in two models of Structural Firefighting helmets – the F20 European helmet and the traditional North American styled F18. The flexibility of the Impact protection system gives the company the freedom to apply it into a range of future products.

Product certifications:

F20: AS/NZS 4067:2012, CE EN443:2008, NFPA 1971:2018

F18: NFPA 1971:2018